Application > Process Piping

Process Piping

Comprehensive solution for everything related to process piping

Details

Process piping is ubiquitous to most industries that during their manufacturing process are required to transport materials through their factory plant. Specific codes and regulation are considered when designing these systems of pipe but every single one of these industries have one key requisite: the fitness for service of the piping materials and it’s joint connections.

The assembly and welding of process piping are a well known challenge for testing and inspection given the variety of sizes and shapes of components and accessibility to the test areas.

Our solution tackles every one of these challenges.

Volumetric Weld Inspection

Phased Array Ultrasonic Testing (PAUT) in combination with Time-of-flight Diffraction (TOFD) is the de facto standard for volumetric inspection of welds.

Our portable PAUT flaw detectors have a fully code compliant PAUT and TOFD calibration procedure, together with a very user-friendly interface , the PragmaVU, allowing inspectors to quickly configure their units, scan and analyze the data with maximum comfort.

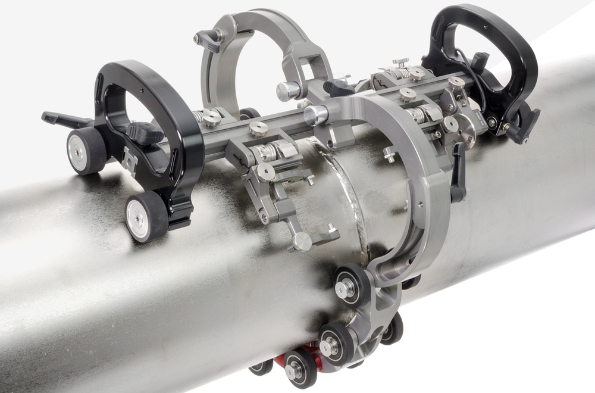

Full range of scanners and probes

Regardless of the component configuration and size, our portfolio of scanners and probes addresses every case scenario, whether it’s new weld fabrication, root erosion or even complicated corrosion on elbows and tees, we got it covered.

Single side Scanning

Due to the geometry of certain pipe fittings and space constraints, testing is limited to single side scanning. There are obvious limitations in terms of defect detectability when only one side of the weld is available.

A careful scan plan must ensure that this limitation is compensated thoroughly using simulation software with ray tracing capabilities. Our Pragma 3D software has such capability and when complex 3D shapes are required to be inspected, like elbows and tees, it is the perfect addendum to your inspection setup.