Application > Automotive

Automotive

Application notes for everything related to automotive NDT

Background

High and Ultra-high strength steels are extensively used in the production of car body components, especially of those that are crash safety relevant. Such components must fulfill high requirements, considering strength and crashworthiness.

Welding of these components is considered a challenge, due to their martensitic structure and high stiffness, which may cause various defects in the welded joints.

Challenges

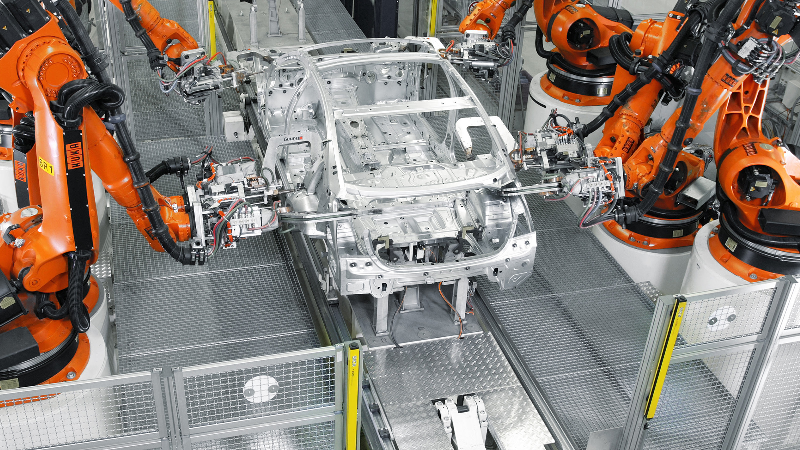

The car parts that need to be inspected for this application vary in shape, thickness, and surface condition from one to the other. They are geometrically complex, both on the exterior and interior. Also materials, joining processes vary tremendously and in turn that adds to the complexity of quality control testing.

Resistive Spot Weld

Conventional ultrasonic testing has been a staple for spot weld evaluation. This method has, like many others, it’s intrincacies since it requires a careful inspection plan and thorough probe positioning in regards to the weld nugget for a proper assessment. Phased Array simplifies this process with a wider footprint and an instant overview of the entire weld nugged (C-Scan), allowing for a proper sizing of the said weld nugget. It’s considerably less demanding on the operator and it’s also entirely possible to automate the entire process, which in turn increases reliability and consistency of results.